Products

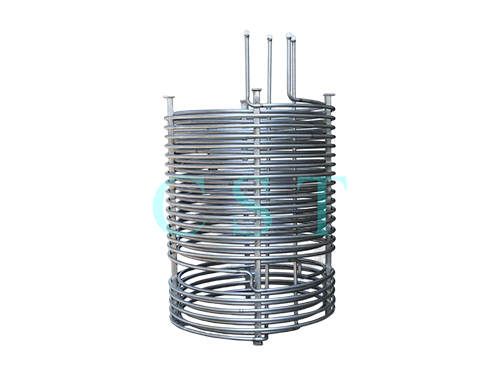

Inline Chemical Heater CSCH

CSCH Chemical Series offers the safe heating capabilities in a complete heating system.

With stainless steel wetted materials this heater is suitable for either single pass or recirculating applications for heating a variety of chemicals.

Offers outstanding performance over a wide range of flow and temperature requirements.

Suitable for chemical heating

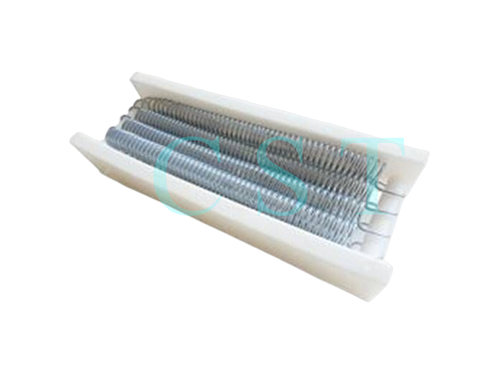

Indirect heating provides an evenly heated surface

Low watt density design reduces surface temperatures and hot spots

Improves chemical longevity and performance for temperature-sensitive chemicals

More available heating power than other inline chemical heaters

Lower mass faster response time

Minimizes fluid pressure drop even at very high flow rates (>60 LPM)

Crevice-free design eliminates dead-zones

PID temperature control provides precise and stable temperature for improved process consistency and yields

Minimizes temperature fluctuations with flow rate changes

| Wattage: | 72-288kw |

| Voltages: | 380V, 400V, 480V, 3~ |

| Standards: | CE |

| Inlet/Outlet: | Flared tube, Union, Flange |

| Wetted surfaces: | 316SS, Ha C276 |

| Minimum water flow rate: | 0 lpm |

| Maximum water flow rate: | 200 lpm |

| Process temperature outlet: | up to 95℃ |

| Temperature accuracy: | ±0.5 ℃, depending upon operating conditions |

| Liquid pressure range: | 10-100PSI (PRV set to 100PSI) |

| Remote interface: | Yes(with RI option) |

| Communication: | RS485(with RC option) |

| Dimension: | 120(W) *80(D) *200cm(H) (144kw) |

| Standard Safety Devices: | EMO Pressure Relief Valve (PRV) Ground Fault Protection (GFP) Electrically grounded heating chamber construction Flow Sensor, Pressure Sensor Safety Limit Control (SLC) Heating Column Current Sensor Bimetallic heater over temperature sensor(s) Heating column over-temperature protection Solid state relay (SSR) overheat bimetallic sensor Sensor failure detection Control circuit fuse protection |